Recent Articles

Turmec works on PRF plant upgrade for Biffa Aldridge

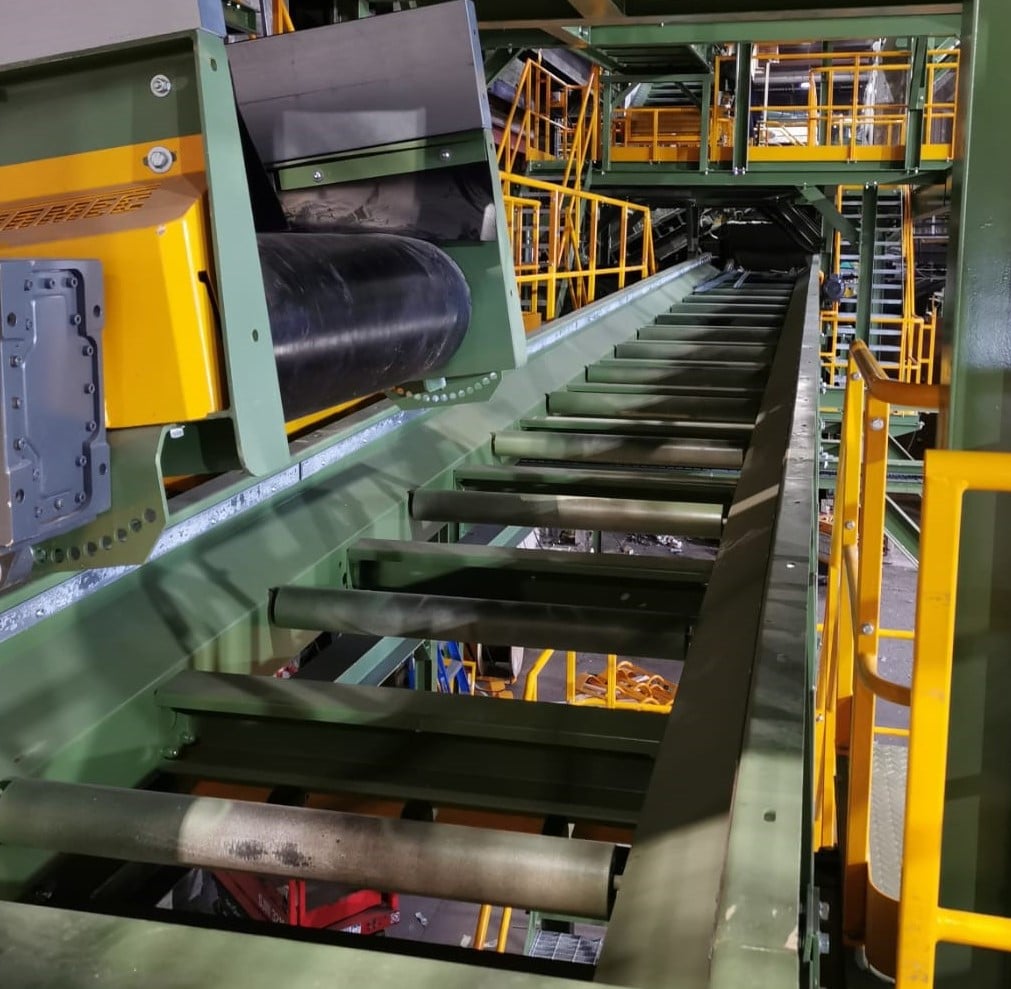

Biffa’s Aldridge MRF is one of the largest MRFs in the UK processing up to c.300,000 tonnes of recyclate per annum. The plant accepts dry mixed comingled and segregated recyclate sourced from local authorities and commercial customers. Paper, cardboard, aluminum, steel, glass and plastics are processed at the plant. In late 2020, Turmec was awarded with the challenge of upgrading the MRF into a PRF (Plastic Recycling Facility) plastics, cans & glass, utilizing high levels of automation to achieve high recovery rates using little manual labour.

Turmec was tasked with installing the upgrade around current operation’s, maintaining production for as long as possible. The project was completed using a scheduled 3 week shutdown leading to minimum disruption to operations.

Turmec used a 3D scan which offered a vision of how the new plant would integrate into the existing facility. Dividing block walls were removed and un-used gantry rails to allow the removal/installation of equipment.

Turmec’s upgrade was delivered successfully, carried out around existing works and we look forward to commissioning the works end April early May

Our client Biffa should see significant reduction in manual labour as well as increased recovery and decreased contamination – up to 99% purity levels in different streams.

About Turmec: Turmec has nearly 50 years of experience in the engineering and recycling industries. We plan, consult on design, manufacture, install and support the very best recycling solutions. Follow links to get more information on Turmec products like Comingled recycling, Refuse Derived Fuel solutions, Mobile industrial shredders, Compost machine, Tyre Recycling Machines and more.

Share this entry

-

Share on Facebook

Share on Facebook

-

Share on Twitter

Share on Twitter

-

Share on Linkedin

Share on Linkedin

-

Share on Tumblr

Share on Tumblr